Company Profile

Bharath Auto Cables Pvt. Ltd. is an ISO 9001:2008 certified company . We are a major presence in the value-added business of wire harness for heavy duty Vehicle , Battery cable, electronics and industrial harness. We pursue rigorous quality standards that make our range flawless and reliable. Our extreme quality and quick delivery system has helped us immensely in gaining our wide customer base in every nook and corner of the country.

We embarked on an ambitious and magnificent journey in the year 2001 and commenced its first wiring harness company at HOSUR in southern India for supplying bus body wiring harness to major OEMs . Also we are into the manufacturing of Engine wiring harness, wiring harness for testing board, Engine test rig breakout box, wiring harness for earth moving vehicle,battery cable, Digital board wiring harness is based on the advanced technology and holds the capability to withstand strong vibration.

BAC as an ISO 9001:2008 Certified company , we believe in utmost customer satisfaction through our qualitative range of product.

Our wide range meets all the existing and recommended standards of the industry. Apart from manufacturing standard range, we also offer customization as per the specification, received from our esteemed customers.Under the leadership of our founder Mr M.P.Baskaran,with every passing day we are touching new heights.

Flexible Supply

At BAC, our teams of skilled professionals are focused first and foremost on meeting the needs and expectations of our customers.

Having an engaged team that understands how their own contribution and performance, influences the outcome allows each team member, to effectively contribute to the production of quality products and provide excellent customer service.

It also enables us to be agile and flexible, ready to respond quickly to meet project adjustments or short timeframes. Direct communication with our engineering support team and production floor team leaders makes it possible to accommodate your changing schedules.

Our prototype services help speed up your new products to the market. Our technical support staff assists in completing documentation of your product.Our BAC Team takes pride in their work and is always ready to provide a high level of customer service and professional execution of projects, all to meet the needs and expectations of the most exacting customers.

Why Do Business with Us?

- Empowered team-based culture that drives high quality, consistent on Time Delivery and excellence in Customer Service.

- Full time prototype team help you to reduce costs through component selection and product development.

- Experienced people to provide assistance in taking cost out of your products.

- Well defined customer focused quality program.

- We work closely with important component suppliers to give you a direct link to the engineering support available from these suppliers.

Our Clients

Prototype development

BAC engineers understand that a new project, often starts with a prototype or very limited production volume. Working as partners during this initial stage, can result in a better product. Our teams will work closely with you and your team to optimize the design and function of wire harness, cable, box build, etc.

Additional benefits of BAC prototyping services include:

- Quick and economical turnaround of small volumes.

- Identifying opportunities to reduce labor without sacrificing quality.

- Providing assistance with layout, routing, materials of construction, component selection and design.

- Providing preliminary cost data and pricing for larger volume production.

Testing and control

BAC utilizes a variety of testing and process controls, to ensure the highest level of quality, and most consistent level of conformity, in our custom wire harness, cable and electro-mechanical assemblies. Used to verify electrical connections, our processes may include optical inspection, electrical verification, in-circuit test, probe and functional test systems.

Additional benefits of BAC prototyping services include:

- Pull force inspections.

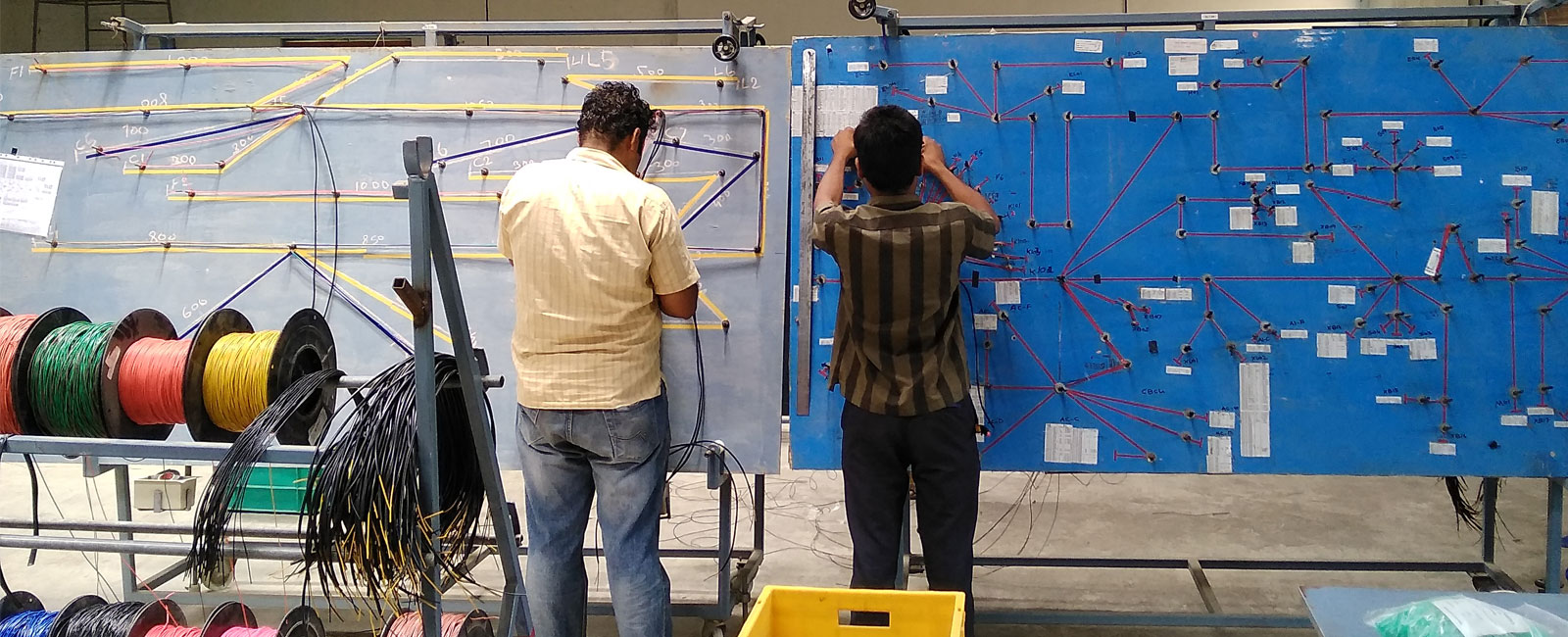

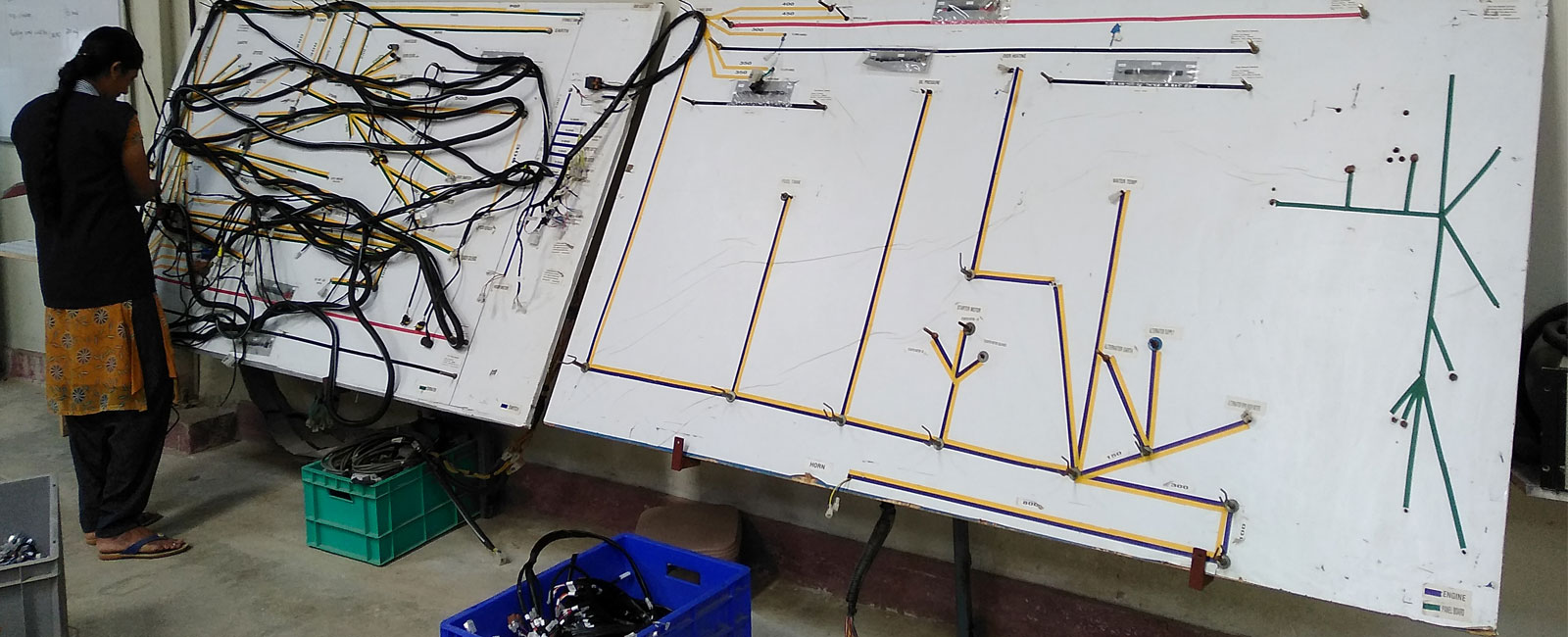

- Custom test boards for electrical circuit continuity, physical layout of harness assemblies and insulation resistance testing.

Engineering Capabilities

BAC offers complete engineering solutions for wiring harness under the guidance of experienced and qualified group of engineers. Our engineering services include:

Design

- 3d solid modeling (Auto Cad)

- Tooling and assembly fixture designs

- Design reviews and feasibility studies

Testing

- Customized testing solutions, including defect prevention and detection systems

Sourcing

- Component sourcing expertise

- Equivalent substitution recommendations

Support

- Customized product support

- On-site engineering support for design and engineering solutions

Value-Added

- Quick turn-around time from quotation to production delivery

- Value Engineering

- Cost Reduction/Cost Avoidance

- Cost reduction through process and product improvements

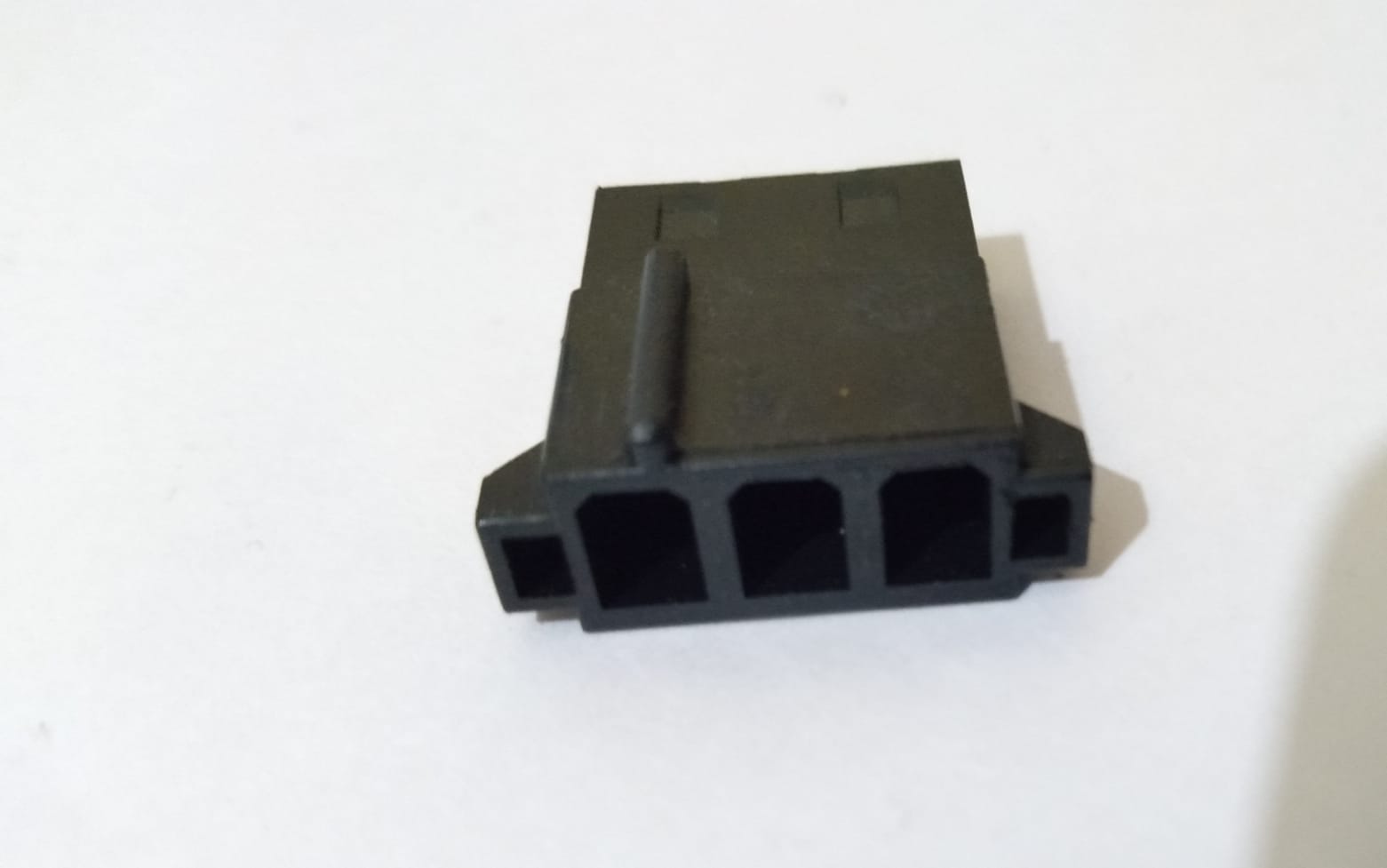

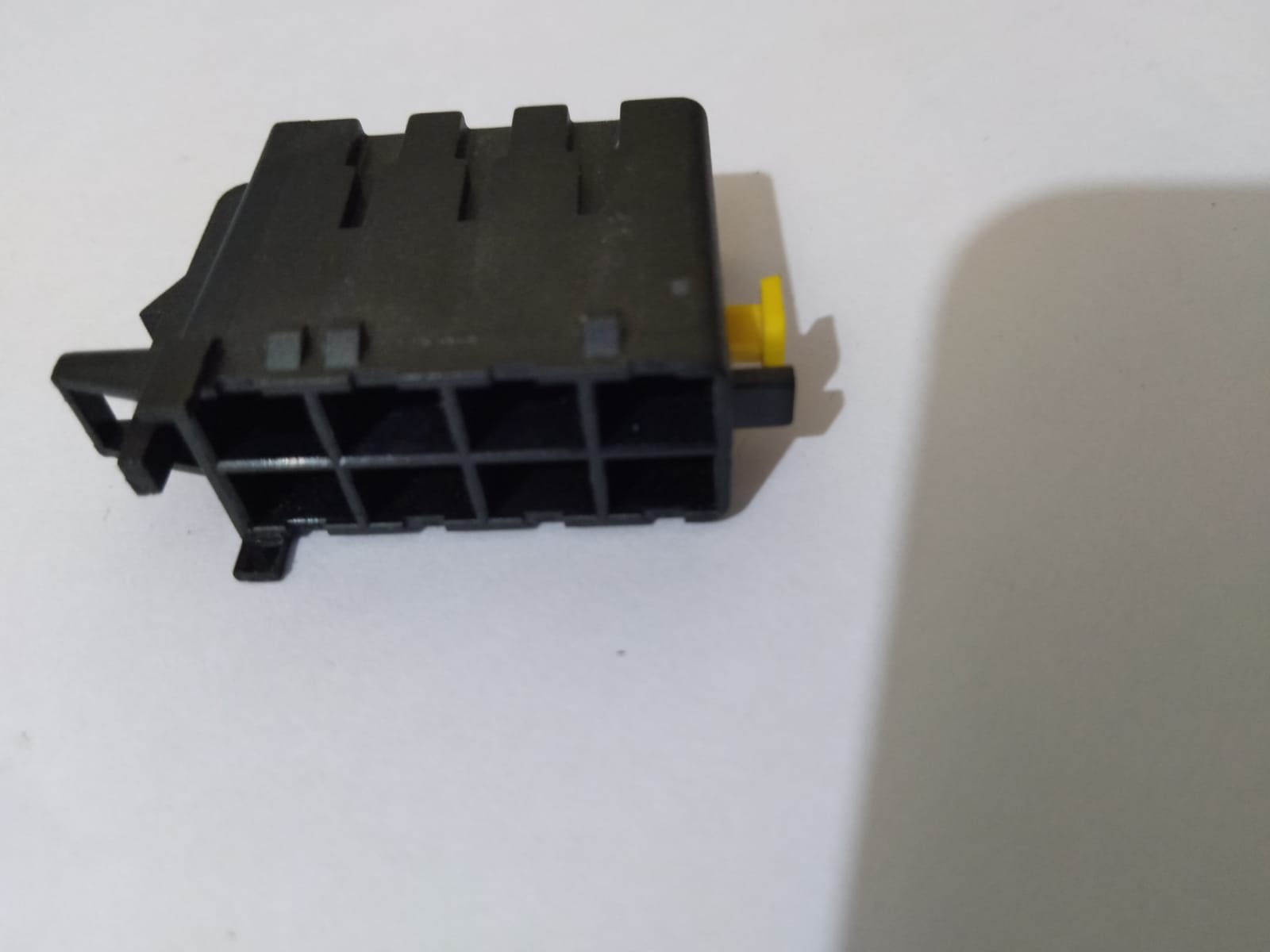

Products

- Bus body wire Harness

- Earth Moving Vehical Wire Harness

- Engine Wire Harness

- Engine test rig breakout box

- ITS

- Battery Cables

BAC has experience manufacturing wire harness for many different markets and industries. These markets include Bus body, Earth moving Equipment, Breakout box, Battery cable, In-house capability for design and manufacturing of applicators, jigs, assembly boards and circuit checking boards, enables process design control and flexibility.

This broad industry experience, allows you to benefit from the vast knowledge, of components and manufacturing techniques, that BAC works with. Today as equipment and machinery, moves to higher technology electronic controls, wire harness needs are evolving as well.

You need a wire harness and cable assembly manufacturer, who has the product capabilities to work, with the new high technology components and cross market applications. BAC has the industry experience and product capabilities, to master the challenges of today's high technology requirements. Delivering you the technology solutions, you need on-time at the most competitive price.

Bus body wire Harness

We are into the manufacturing of wiring harness for Bus body. These are designed as per the OEM specificaiton, and thus reduce any sort of discrepancy in design and size. The electric wires used for the purpose, consists of the conductor made from numbers of twisted mild copper wire, having a diameter of less than 0.5 mm, and the insulator surrounding the conductor.

Earth Moving Vehical Wire Harness

Our range of specially crafted wiring harness for Earth moving equipment are ideally made by keeping in mind the various intricacies, of such sort of machines. These are well received in the industry circle, for their high performance and reliability.

Engine Wire Harness

We offer high quality wiring harness for Engines. We also design and develop the wiring harness, as per OEM specification. These are manufactured as per the existing parameters of the industry. Our range is well acclaimed in the industry circle, for its flawless wiring and optimum reliability.

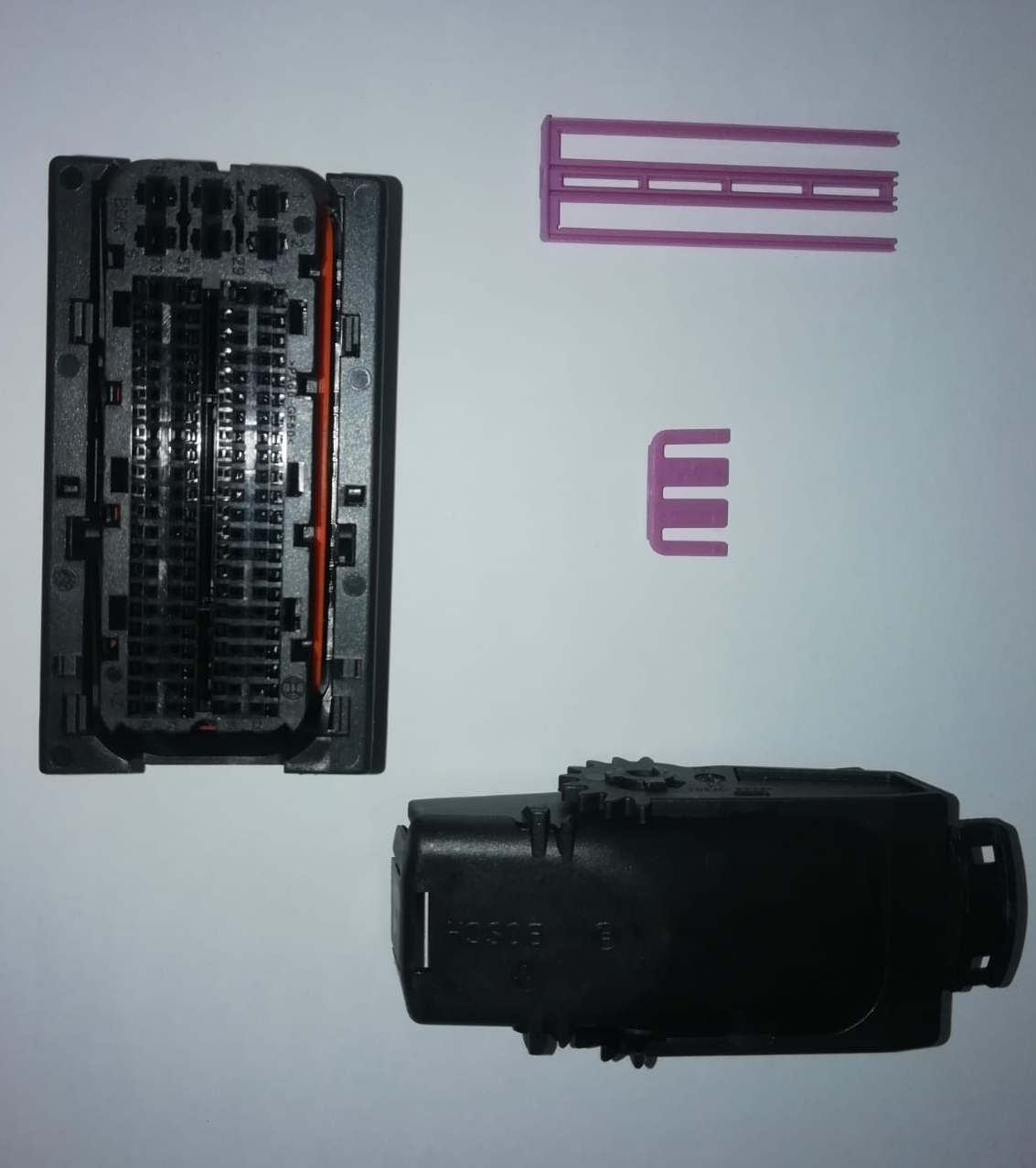

Engine test rig breakout box

We are into the manufacturing of Engine test rig breakout box. These are designed and developed as per the OEM specification and thus reduced in size.

ITS

We are into intelligent transport system wire harness as per specification.

Battery Cables

We are into manufactures of battery cable ranging from 25 sq.mm to 90 sq.mm. We also have braided cables.

Quality

BAC is dedicated to achieving the highest level of quality from our skilled workforce, as well as all assemblies and products produced. It's what our reputation has been built on, over more than 13 years in business.

BAC is dedicated to achieving the highest level of customer satisfaction, by meeting expectations in providing competitive products and services. We recognize that an emphasis on quality is essential to our customer's success, as well as our own. Our Quality Policy extends to all our manufacturing locations, and is built upon the following strategic principles:

- Maintain a healthy and empowered team environment.

- All employees and supplier partners are responsible for quality and customer satisfaction.

- Implement industry leading quality management and measurement systems.

- Adhere to corporate, governmental and environmental quality obligations and measurements.

- Commit to flawless execution and encourage a philosophy of defect prevention.

- Continually improve quality performance in all areas of the business.

Contact Us

Address: 1/147B,Enupasandiram Road,Bagalur Road,Nallur Post,Hosur-635103. Krishnagiri(Dist.) Tamil Nadu

Email: info@bharathautocables.in

Tel: +91 93443 11019 |

+91 93623 11019